This is one of those times when I wish life was a little more like TV. Or at least all those renovation shows that I love to watch on TV. You know how they always seem to be halfway through a big project on those shows and then one of them gets an idea for something they want to add, or do differently and everyone else groans because that idea will add on, like, 3 more days of extra work time! And everyone on the show is walking around saying “Oh no! This is so annoying! We’re sooo far behind now!” You know exactly what I mean. Well, I laugh in the face of their 3 more days! Ha! Ha ha ha!

Of course, in real life, when you’re working on a project and you get an idea to change something, no matter how small, it seems like it always adds on something like 3 more months to the project. At least.

That was the case with these mouldings on our kitchen cabinets. This was meant to be a quick-fix kitchen update that we started last fall, but as we got more and more into it, we realized that we were really going to have to change some of the trim out. We could tell that it would look amazing and we just couldn’t not do it. But of course, then we went on leading our normal lives and didn’t have time to get to this extra little update until this Spring. So by that time, I just wanted the project done and out of the way so we could actually start enjoying the new kitchen updates. And then, as if it was our fate to finish the kitchen, exactly when it was really starting to bug us the most, GE Sealants stepped in and asked us if we’d like to try out their new fancy-shmancy, super-quick, extra-easy-to-use adhesive. And just like that, kitchen design magic was made!

Let’s start out by looking back a few years at how our kitchen used to look, and then I’ll show you how we quickly updated our cabinets with the new GE Iron Grip adhesive, and I’ll show you how awesome that part of the kitchen is looking now. 🙂

So here’s how it used to look:

Our kitchen has honestly always been pretty enjoyable to be in. The only problem really was that the style was out of date. The cabinets were great quality custom cabinets, but they were golden oak, which instantly made the kitchen look old. That extra gingerbread trim around the windows really gave it a “straight out of 1992” flare that just wasn’t doing it for us. Still, it was a big kitchen and it functioned well, so we made it work.

It’s really only taken a few pretty minor and inexpensive changes to make it feel like a brand new room and this little cabinet project has definitely played a big part. We started out by painting all the cabinets a light grey color and that really made a huge difference. The room really brightened right up but we could tell as soon as we finished painting that removing all that extra trim would really make the whole room feel so much more open. It was one of those jobs that really extended how long this whole project took by a lot, but in the end it was worth it.

So down came all that trim!

We removed those little wavy pieces over the windows as well as all the trim running along the tops of the cabinets.

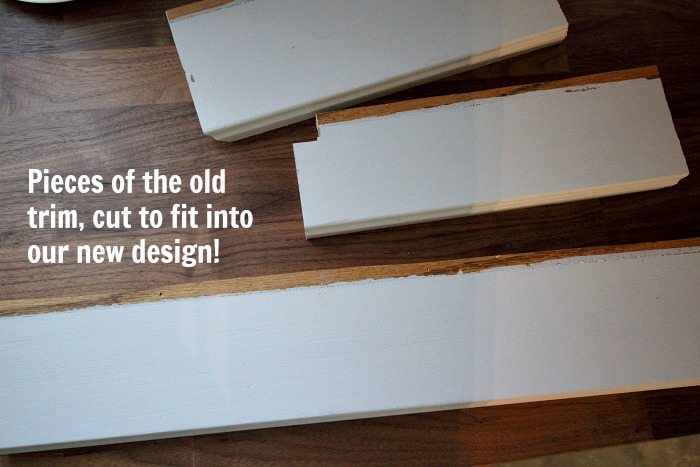

We were actually able to cut those same pieces of oak trim down to fit our new design, so that was really convenient and affordable too! Instead of having one long piece of trim running all along the ceiling and joining all the cabinets together, we decided to trim out each individual upper cabinet. That really maximized the openness of the ceiling and kind of gives the feeling of individual pieces of furniture in the room. I love this look for a kitchen because it’s both an updated look and also totally appropriate for an old farmhouse like ours.

This was a pretty simple job overall, but one with a really big impact. Those are always the best projects aren’t they?

We really only needed a few basic supplies, other than the miter saw which is out in the garage.

We gathered some painting supplies, our handy-dandy cordless brad nailer, and some GE Iron Grip adhesive.

When it comes to adhesives, this one is definitely a winner. It sticks to pretty much anything, whether porous or non-porous, even things that are typically difficult for other adhesives like steel, PVC, glass, concrete, and porcelain, and since it’s 100% silicone it won’t shrink or lose adhesion over time. Plus it works super-fast, which is really the key to my heart. In projects where you need to clamp something and let it dry, it builds strength quickly and offers up to 75% less clamp time than many other adhesives! So it’s basically the new glue of choice around here. 🙂

Here are our largest moulding pieces, all cut out and ready to go.

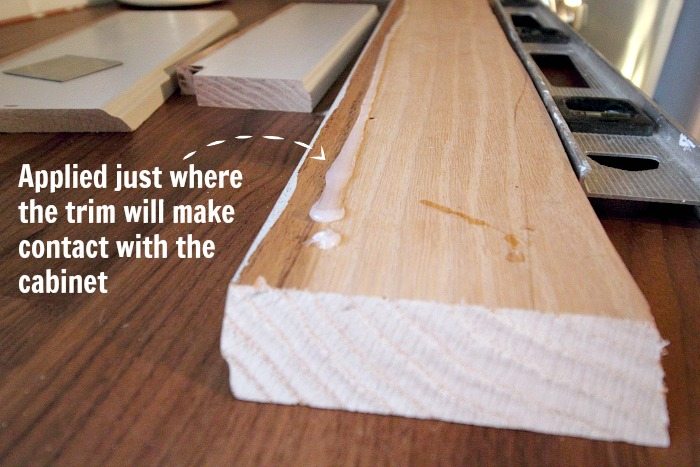

We applied a bead of adhesive to them…

…and then we tacked the trim in place using just a couple of nails from the brad nailer.

There isn’t really any way of using clamps on cabinets like this, so a couple of small nails were able to hold the heavy oak trim in place for us until the adhesive dried completely.

I really appreciate how this adhesive is clear and not yellow-ish, so it won’t mess up the nice clean look of our freshly-painted cabinets if we accidentally use too much!

So here’s how that part of the trim looked after we got the main part of the mouldings back in place. Of course, removing the original trim exposed a lot more than just the tops of the cabinets! The whole vent hood area will be addressed soon and I’m really excited about the idea we have for that!

We exposed some wires and some random pink uglyness above the sink too, so we added in a nice thick piece of crown molding to give that part of the room a nice finished look.

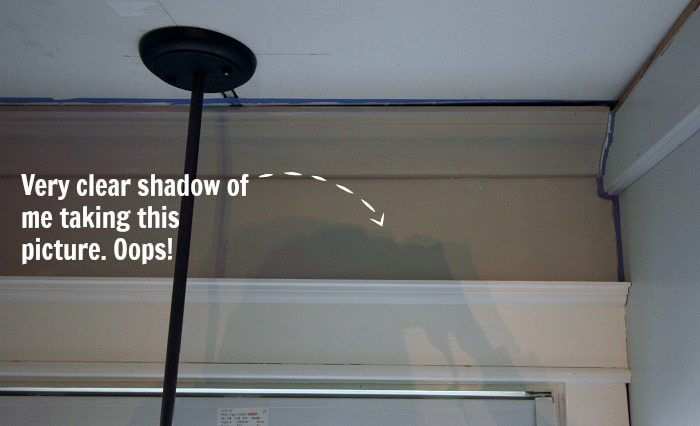

I painted that whole area out in the same color as the rest of the walls in the room, but something still wasn’t quite right.

There are always unforeseen gaps and weird angles when you’re working with old houses like this! Arg! Sometimes those gaps aren’t really a big deal, but sometimes they can just ruin the whole look of a room.

Chris cut this long skinny wedge to fit right into the gap. Adhesive is perfect for a situation like this because any other form of fastening either wouldn’t have anywhere to hold on to, or would split the tiny piece of wood. We just spread a little bit on the edges of the wood with a piece of cardboard and popped it into place!

I finished up with a nice bead of caulk over the whole area.

Instead of a weird dark gap, it’s looks nice and clean! We also fitted a little piece of wood over the little trench in the ceiling where the wires were. Again, adhesive is great for this because you don’t want to risk having a nail or a screw slip even a fraction of an inch in a situation where you’re so close to wires!

Of course we really (really really) need to get those ceilings painted once all of these little finishing touches are done on the room! Soon I hope!

So here’s how the room looks now with the trim at the top of the cabinets all finished up! We added in another thin moulding right where the thicker piece meets up with the ceiling, again reused from the original trim in the room, to finish things up.

Here’s that “before” shot again!

And now!

You can see we’ve made a few other changes in the room too. More on those soon!

A special thanks to GE Sealants for sponsoring this post and helping us tackle this project so quickly and easily! I was compensated for my time spent writing this post, but all opinions and ideas are mine as always!

Courtenay Hartford is the author of creeklinehouse.com, a blog based on her adventures renovating a 120-year-old farmhouse in rural Ontario, Canada. On her blog, Courtenay shares interior design tips based on her own farmhouse and her work as founder and stylist of the interior photography firm Art & Spaces. She also writes about her farmhouse garden, plant-based recipes, family travel, and homekeeping best practices. Courtenay is the author of the book The Cleaning Ninja and has been featured in numerous magazines including Country Sampler Farmhouse Style, Better Homes and Gardens, Parents Magazine, Real Simple, and Our Homes.