Yay! We’re getting really really close to being able to say that we’re mostly done with our little kitchen update! For now, at least! We always have big plans/dreams for the future, but some of these smaller projects that we do really help us to enjoy our home so much even when we don’t have the time or the budget to do the bigger renovations right away.

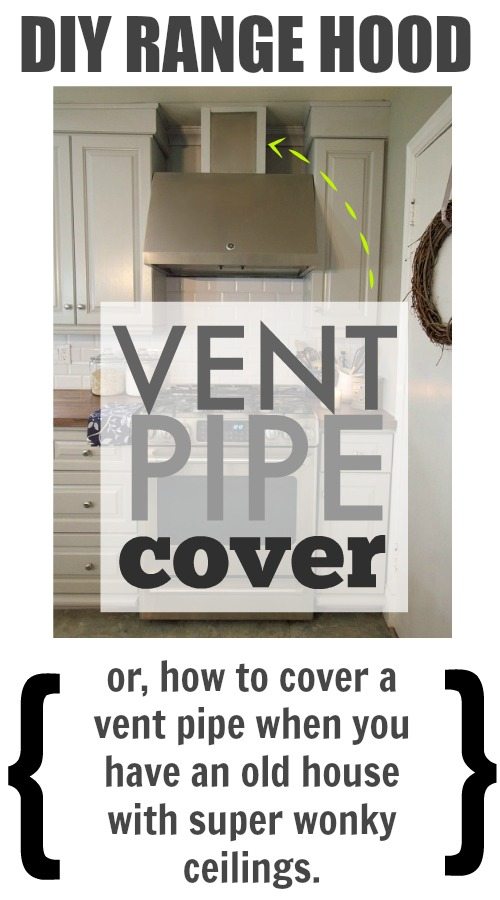

This particular project is kind of weirdly specific, but it came about because of the fact that we decided to re-do the trim at the tops of our cabinets to give the whole room a more open and updated feel. So that left this area over the range hood, that had previously been covered up, exposed. We looked at our options and we discovered that the maker of our range hood does sell just the plain stainless steel tube to cover the vent pipe if yours is exposed, but that tube is really kind of expensive for something so plain and unexciting. And it would still probably end up being a lot of work because we’d still probably need to to cut it down to fit our weird wonky space exactly. So we thought we could DIY something better! 🙂

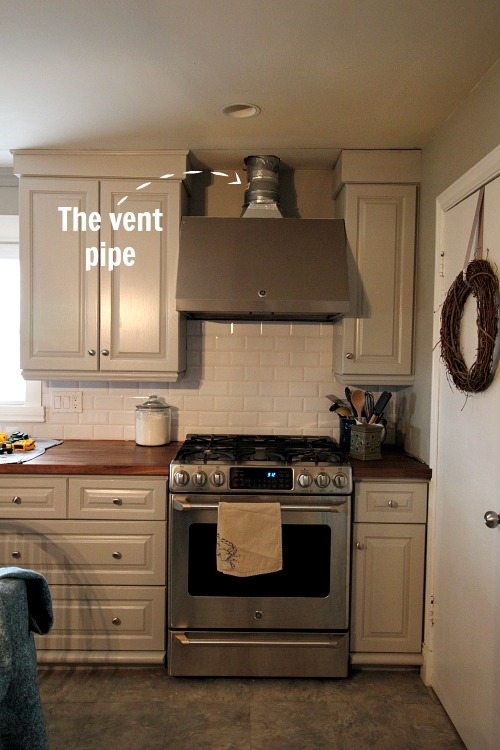

So here’s the area that we’re working with here:

So as you can see, we have a vent pipe and it needed covering. We decided that our best bet would probably be a combination of stainless steel and wood for this project. The wood because it would be easy to work with to get it to fit properly next to our really slopey kitchen ceiling, and the stainless steel to match all the stainless steel everywhere else.

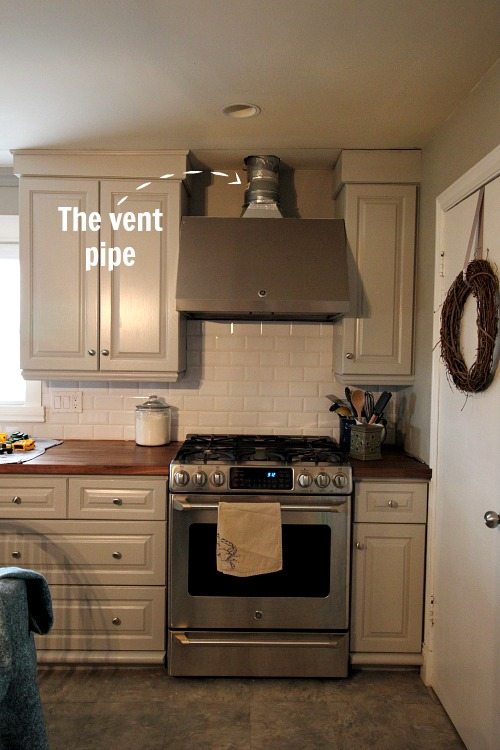

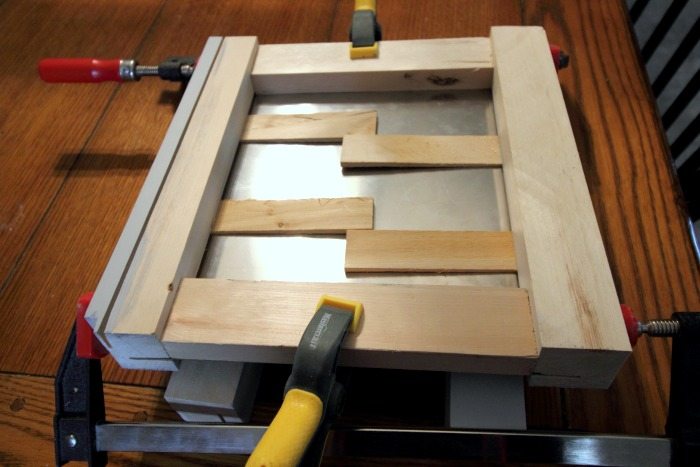

We started out with four “posts” made out of 2×2 pine, sanded them down really well, and then cut slots for the stainless steel to slide into.

Next, I painted the parts of the posts that would be visible with the same paint we used for the cabinets.

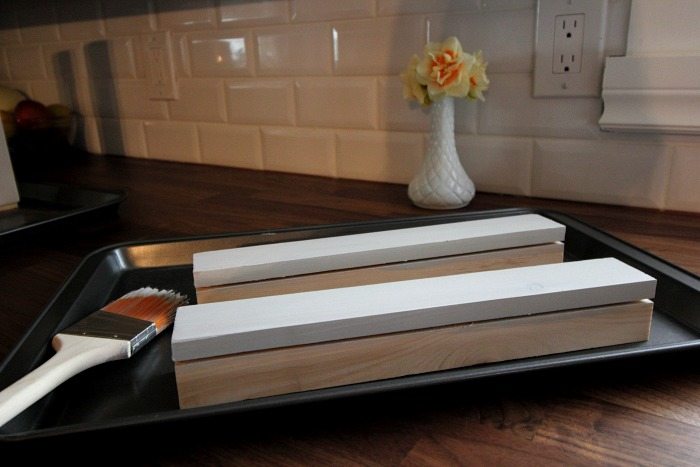

Then it was time to assemble! We had three sheets of 30 gauge stainless steel cut to cover the front and the two sides of the pipe and go all the way back to the wall.

We used GE Iron Grip adhesive to put the whole thing together and that really helped make this project a success rather than a total disaster. You may remember that we used the same adhesive a few weeks ago on our cabinet moulding update. The GE Iron Grip adhesive is allows you to confidently glue pretty much any two objects together, even materials that are typically difficult for other adhesives like steel, PVC, glass, concrete, and porcelain, and since it’s 100% silicone it won’t shrink or lose adhesion over time. We had to get a little bit creative with our assembly methods here because this type of stainless steel actually comes on huge rolls and so it has a slight bend to it. We were able to fix that though, no problem!

That saved us a ton of money. There are heavier stainless steels available, but the cost for the stainless steel for this project would have been about $250 instead of $40. Yay for saving money!

So we applied some adhesive to the stainless steel and some stabilizer pieces and put the first panel together.

The GE Iron Grip Adhesive offers up to 75% less clamp time than many other adhesives so it allows you to work much more quickly on projects like this. We left our project clamped for about 2 or 3 hours and then we had a nice, straight, flat panel!

…or so I thought. Chris always likes to be extra sure so he added in a few shim in the back to hold the stainless steel extra straight.

He was actually able to apply adhesive behind each of those shims and have them hold right onto the surface of the stainless steel, so that really helped give him peace of mind. 🙂

And here’s another picture of the clamping process. I always think these pictures make it look like our projects are so fancy and complicated, even though they never are!

We created another side panel exactly the same way and then brought them together with the front panel so we had a full cover for our vent pipe.

You can see all those shims working their magic back there! Don’t mind the water bottles and soccer gear in the background! Our kitchen table is always set up with all our supplies for the next game or practice lately! 🙂

So at this point, all that was left to do was put the vent pipe cover in place, add a little trim at the top and some crown molding behind, and we were done!

So, again, here’s how it looked before:

And now, just for fun, let’s look at this part of the room way, way before. This was about 3 years ago.

And now!

We’re pretty excited about having a nice fresh, clean, updated kitchen now. It took us a few years, but we got there eventually!

Of course, we really just have some paint to touch up in a few places, some caulking to do, and then we can officially consider this project done! Well, done-ish. 🙂

I can’t wait to share some more of the details about the whole process, what we chose, and why in some upcoming posts!

A big extra special “thank you” goes out to GE Sealants for sponsoring this post and for giving us the motivation to get these last few projects checked off our list! I was compensated for my time spent writing this post, but all thoughts and opinions are 100% mine as always!

Courtenay Hartford is the author of creeklinehouse.com, a blog based on her adventures renovating a 120-year-old farmhouse in rural Ontario, Canada. On her blog, Courtenay shares interior design tips based on her own farmhouse and her work as founder and stylist of the interior photography firm Art & Spaces. She also writes about her farmhouse garden, plant-based recipes, family travel, and homekeeping best practices. Courtenay is the author of the book The Cleaning Ninja and has been featured in numerous magazines including Country Sampler Farmhouse Style, Better Homes and Gardens, Parents Magazine, Real Simple, and Our Homes.